A New York painting contractor is facing nearly half a million dollars in fines for exposing workers to deadly falls. OSHA says the problem was not only a lack of compliance but also a lack of common sense. Keep reading to learn more about this significant enforcement action.

The Nassau County contractor had a long history of fall protection and scaffold safety violations. Now it’s facing an additional $460,350 in fines. An inspection was opened in March as part of a local emphasis program on falls in the construction industry. Many of the hazards identified were similar to those cited during previous OSHA inspections of five other of its worksites over the past several years.

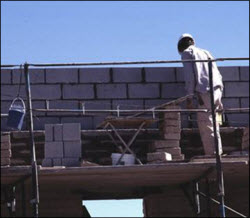

One of the violations was not having a competent person inspect the scaffold during erection. OSHA says an inspection would have identified hazards like missing cross- bracing and planks, lack of fall protection, and exposure to falling objects.

These and other failures earned the contractor 10 repeat citations in addition to citations for new hazards, including erecting scaffolding on unsound footing. The Long Island area director noted, “The sizable fines proposed reflect the ongoing failure and refusal by this employer to provide basic safeguards for its employees. Workers have repeatedly been exposed to deadly or disabling falls and crushing injuries.”

Test your knowledge of scaffold basics

There are three basic types of scaffolds:

- Supported scaffolds consist of one or more platforms supported by rigid, load-bearing members.

- Suspended scaffolds are made of one or more platforms suspended by ropes or other nonrigid, overhead support.

- Equipment like manlifts and personnel hoists are sometimes considered vehicles or other machinery but are actually another type of supported scaffold.

The following hazards are associated with all types of scaffolds:

- Falls from elevation due to lack of fall protection;

- Collapse of the scaffold caused by instability or overloading;

- Being struck by falling tools, work materials, or debris; and

- Electrocution, principally due to proximity of the scaffold to overhead power lines.

OSHA requirements address the two primary groups who interact with scaffolds—erectors/dismantlers and users. Scaffolds must be designed by a qualified person and constructed and loaded in accordance with that design. A qualified person must also preplan to ensure the safe erection/dismantling and use. And a qualified person is required to train each employee who works on a scaffold.

When OSHA revised its scaffolding standard in 1996, government studies showed that 25 percent of workers injured in scaffold accidents had received no scaffold safety training, and 77 percent of scaffolds were not equipped with guardrails. Make sure you’re not cited and fined for these still-common compliance failures.

Learn more about OSHA’s fall protection standards at http://www.OSHA.gov/stopfalls.