On May 19, OSHA’s Region 5 office announced that it has renewed its alliance with the Electrical Joint Apprenticeship and Training Trust (EJATT) in Alsip, Illinois, to help protect electrical workers from arc blast, arc flash, and other hazards associated with the installation and maintenance of electrical systems.

Under the alliance, which was first signed in February 2008 and previously renewed in May 2012, OSHA and EJATT will present training programs, hold forums and meetings on the hazards associated with arc blast and arc flash, and work to develop resources to help employers protect workers from these hazards. In addition, according to OSHA, the alliance is focused on promoting a cooperative relationship between labor and management and encouraging worker participation in safety efforts.

Kathy Webb, OSHA’s area director in Calumet City, Illinois, commented, “The renewal of this alliance reflects the importance of electrical worker safety and health. . . . This alliance will continue to help develop effective training programs, while opening the lines of communication between OSHA, employers, and workers.”

Arc flash hazards and solutions

Arc flash is an undesired electric discharge that travels through the air between conductors or from a conductor to the ground. Arc flash incidents can damage equipment and cause fatalities and severe injuries, including burns, hearing loss, nerve damage, and cardiac arrest.

Causes of arc flash include tools being dropped on conductors, circuit breakers, or other energized parts; improper work procedures, such as working on energized equipment when it should have been de-energized or locked out; and buildup of dust, impurities, and corrosion on insulating surfaces.

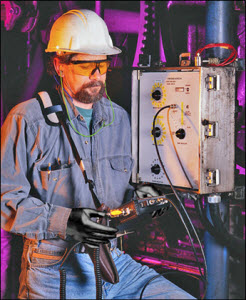

To protect workers from arc flash, de-energizing equipment before beginning work is the most effective strategy. In situations where qualified workers must work on energized equipment, proper use of PPE and electrical protective equipment such as insulated footwear and gloves, nonconductive tools, and flame-resistant clothing helps to reduce the hazard. Workers must be trained to follow safe work practices and use all PPE and other equipment properly.

OSHA recently updated its standard for electrical power generation, distribution, and transmission. The revised rule, which includes revisions to the requirements for electrical protective equipment, takes effect on July 1, 2014, with some provisions scheduled to become effective April 1, 2015.

Share the following tips with workers who must work on energized electrical equipment:

- Always inspect equipment and work areas for arc flash hazards and risks when you enter an area with live electrical equipment.

- Whenever possible, always de-energize and lock out equipment before performing work on it.

- Wear all required PPE, and inspect it before each use to make sure it is in good condition and rated for the specific use that your work calls for.

- Exercise caution and follow safe work practices. Human error, such as dropped tools, contact with electrical parts, and wrong test equipment, is a major cause of arc flash incidents.

- Report and do not use damaged electrical equipment, testing equipment, and other tools.